Tin-plated copper busbar

Tin-plated copper busbar helps upgrade design and provide the best quality for switchgears, switchboards, electrical panels, power transformers and busducts.

Overview

Tin-plated copper busbar helps upgrade design and provide the best quality for switchgears, switchboards, electrical panels, power transformers and busducts by:

- Applications

- Switchboards, Switchgears, Electrical Panels, Power Transformers, Busduct, etc.

- Worldwide Recognition

- Tin-plated copper busbars, complying with International Standards and produced by Oriental Copper, are accepted in principle markets i.e. in Japan, USA, European countries, Taiwan R.O.C., United Arab Emirates, the Kingdom of Saudi Arabia, and more than 50 other countries all over the world.

- Extended Long-Life

- Tin, a soft white metal can easily be polished, scratch brushed or flow melted to give a bright finish. It is non-toxic and is not greatly affected by the organic acids. Sulphur compounds do not readily tarnish tin. It is not impaired by either air or water, but reacts with hydrochloric acid to form stannous chloride. Tin is one of the less susceptible metals to corrosion attack. Tin-plated copper busbar protects against atmospheric corrosion and hence provides longer life when exposed to corrosive atmospheres.

Specification

- Oriental Copper produces and supplies high quality tin-plated copper busbar as per International Standards such as JIS, DIN, BS and ASTM.

Process: |

In-house tin-plating controlled by computerized system |

|---|---|

|

The Purity of Coating Material: |

Tin anode, 99.5% up |

|

Coating Thickness: |

3 - 30 microns and as per customer's requirement |

|

Mill Test Certificate: |

- Adhesion Test |

Consistent Tin-Coating

- Oriental Copper X-ray tests the thickness of tin coating using a computerized system which is recorded in our Mill Test Certificate. Our customers can be assured of the consistency of the tin-coating.

Better Joint Efficiency

- Tin-coating applied to the contact surfaces prevents or delays oxidation when operating in high temperatures or in extreme environments for long term usage. Oriental Copper produces and supplies high quality tin-plated copper busbar that improves the jointing surface effectiveness and reduces the electrical resistance of the joint.

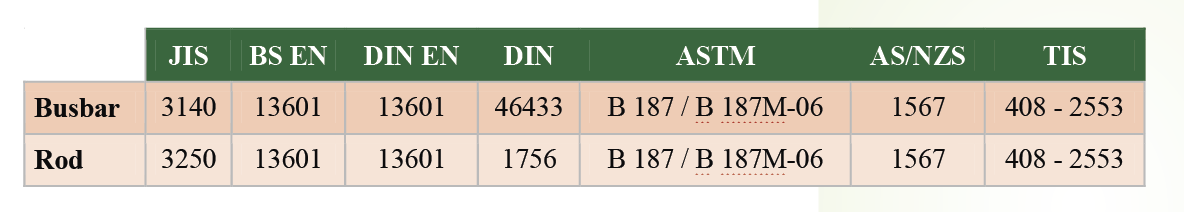

Standards

Copper busbar and rod are produced to meet International Standards including JIS, BS EN, DIN EN, DIN, ASTM, AS/NZS and TIS as required by customer specifications.

OC's Quality Assurance

- Precision measurement by CMM and modern measuring instruments

- Control according to International Standards and customer specifications

- Mill Test Certificate

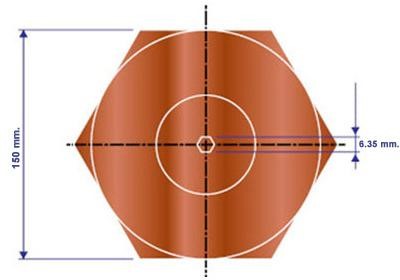

Size Range

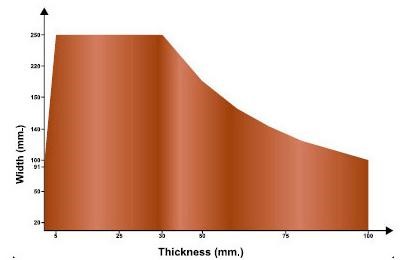

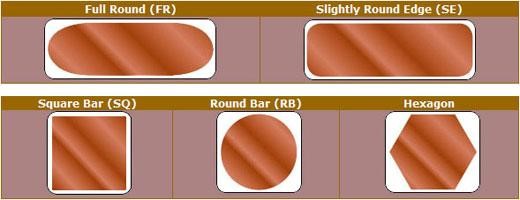

Rectangular Bar (FR & SE)

Width 9.53 mm. up to 305 mm.

Thickness 2.5 mm. up to 100 mm.

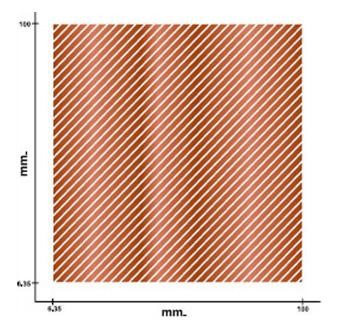

Square Bar (SQ)

Dimension 6.35 mm. up to 100 mm.

Rectangular Bar (FR & SE)

Width 9.53 mm. up to 305 mm.

Thickness 2.5 mm. up to 100 mm.

Shape

Wooden Boxes: Copper will be wrapped with insulated paper and plastic.

Bundles: Wrapped with insulated paper and plastic.

Let us know how we can help you. Our team is ready to discuss your business needs and answer any questions you may have.

Explore Other Products

Explore Other Market Solutions

ICT & Data Center

Marine

Healthcare

Electronics

Mining and base metal refinery